No trend has and likely will transform or revolutionize the chemical industry processing as much as the implementation and integration of technologies can. The digital transformation of chemical industries includes custom software, ERPs, IIoT & IoT sensors, Robotic Process Automation, CAM systems, BPM platforms, and other automation systems.

The Industrial Automation Services Market is expected to grow to $264.69 billion by 2026. The popularity of implementing Industry 4.0 can explain this rapid growth of workflow automation among the chemical industries, which emphasize productivity, regulatory, and safety compliance. by 2026. The popularity of implementing Industry 4.0 can explain this rapid growth of workflow automation among the chemical industries, which emphasize productivity, regulatory, and safety compliance.

APAC countries are leading the way in integrating automation technologies, particularly within the chemicals sector. This trend is now being followed in North America and Europe by chemical industries mainly due to the growth of industrial chemical production and market demands.

The digital transformation of chemical industries revolves around software development, data (AI/ML) solutions, IoT and IIoT, robotic process automation, low code platforms, and product modernization, contributing to custom workflow automation.

Why Are Chemical Industries Seeking Custom Workflow Automation?

Automation ensures accuracy and consistency in processes, enhancing resource utilization and maintaining safety standards without compromising production quality. It also offers scalability by managing multiple processes simultaneously, boosting production output, and lowering chemical industries’ operational costs.

Chemical industries face certain challenges with traditional chemical processes, the challenges are:

Increased Downtime and Lower Productivity

Traditional chemical industry processes often lead to increased downtime and reduced productivity due to their inefficiencies, reliance on manual labor, and susceptibility to equipment failures. Manual monitoring and control of processes can result in slower response times to issues, leading to extended downtimes.

Supply Chain Irregularities and Management

Managing complex supply chains involving raw materials, intermediate products, and finished goods is challenging. Unexpected events such as wars, geopolitical tensions, pandemics, and major weather events can disrupt supply chains.

Data Mismanagement

With traditional workflow systems chemical industries face data irregularities. Wrong data inputs and human errors fail to give accurate data or information, leading to bad decision-making and strategic planning related to production and business.

Regulatory Compliance

Compliance with various safety, environmental, and quality standards is complex and time-consuming. The industry requires significant resources and expertise to meet regulatory requirements.

Quality Control

Strict quality control is essential to ensure the safety and efficacy of products. Technological advancements are crucial for improving consistency and accuracy in production processes, reducing the risk of errors and deviations.

Operational and Process Control Challenges

Chemical production involves complex and hazardous processes that pose safety risks and require careful monitoring of critical parameters. This often involves using robust equipment to monitor operations in inaccessible areas, such as underground pipelines and high-temperature or high-pressure zones, to ensure safe and efficient production.

Inventory Management

Traditional chemical industry processes often cause overstock and stockout issues due to inefficient inventory management and a lack of accurate demand forecasting. Overstocking and stockout result from outdated manual tracking systems and reactive, rather than proactive, inventory practices, making it difficult to maintain optimal inventory levels and balance supply with demand.

How Can We Help The Chemical Industry Have a 25-30% Cost Reduction with Custom Workflow Automation?

According to an IBM survey, over 80% of chemical industry executives believe that artificial intelligence will significantly impact their business within the next three years. AI is quickly becoming an essential component of the chemical industry, with the global AI-in-chemical market projected to reach approximately $16.94 billion by 2032, growing at an impressive rate of 31.9% from 2023.

30-35% Increased Production Efficiency

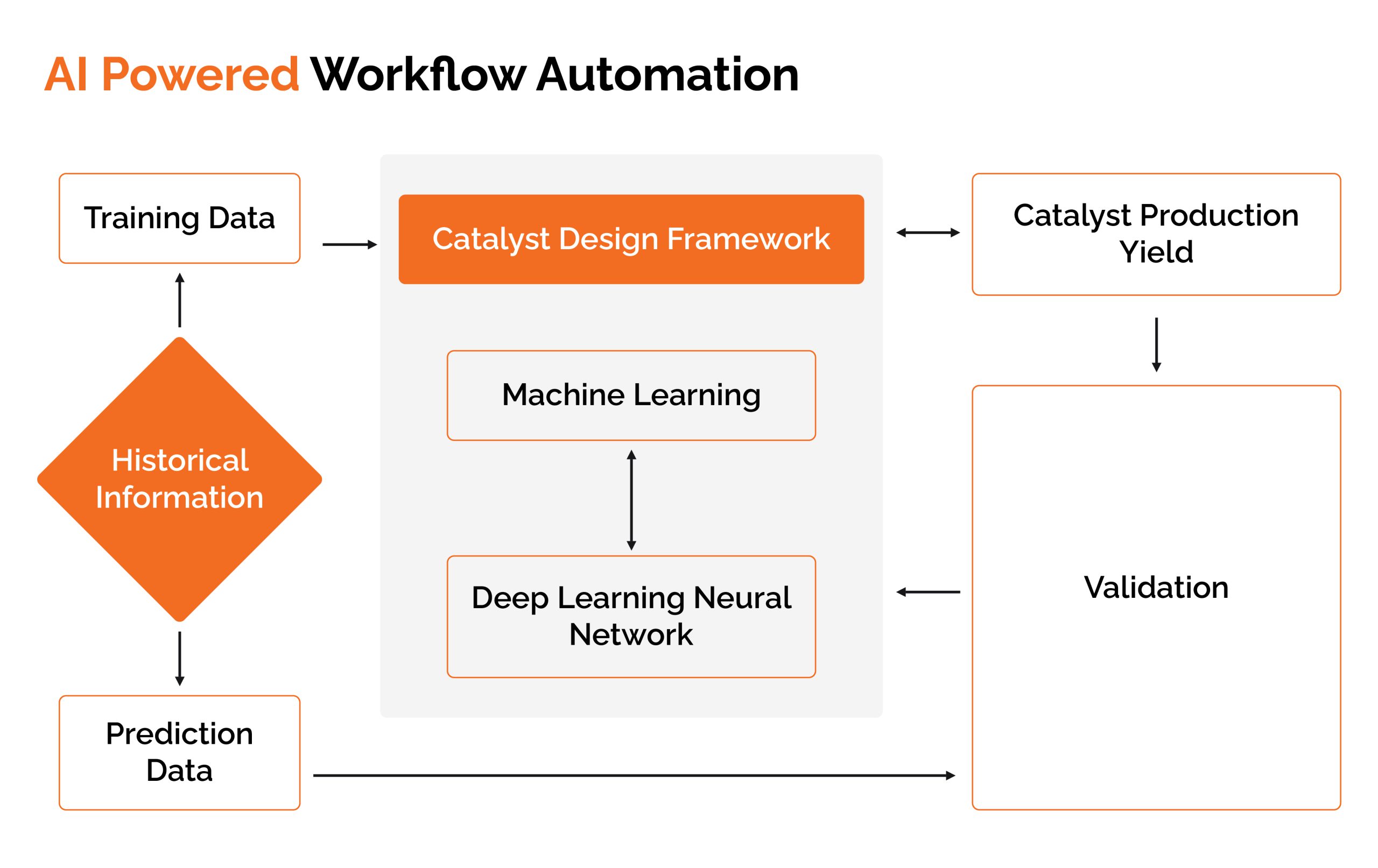

Custom workflow automation in chemical manufacturing optimizes production stages such as quality control, process improvement, failure prediction/prevention, and safety monitoring. We develop advanced AI/ML algorithms using data to manage complex chemical reactions, maintaining consistent quality, maximizing yield, and preemptively enhancing safety by anticipating hazardous conditions.

Custom workflow automation enhances operational optimization, resulting in higher yields for companies. Through AI-driven root cause analysis and testing procedures, scrap rates are reduced, and product quality is improved. These algorithms also stabilize workflow and boost equipment efficiency. Organizations can adapt to various production variations using AI tools, which can automatically control conditions such as stirring rate, temperature, and process duration.

20-25% Lesser Time For New Product Development

Our AI/ML integrated custom workflow automation accelerates and enhances the accuracy of the R&D process by leveraging ML tools to discover, and recognize molecules, formulate precise chemical proportions, and define quantities. AI analyzes potential chemical combinations to predict their effectiveness for specific purposes.

With custom workflow automation chemical companies can create new products in less time using limited resources and enhancing the R&D process. It facilitates less time to market and gives a competitive advantage to the manufacturer allowing them to market the product without any competition and generate revenue.

30-35% Improved Inventory Management

Traditional forecasting systems struggle with the vast data available online. Our AI algorithms analyze this data to forecast product demand, allowing companies to optimize production planning and increase cost-effectiveness. Additionally, AI can gather point-of-sale data to predict customer demand and reduce waste from out-of-demand items. Improved inventory management helps in timely production, and delivery and less resource wastage that eventually helps in reducing expenses and boosting the ROI and revenue flow.

50% Error-less Inventory Forecasting

ML and AI-enabled custom workflow automation models with advanced analytics accurately predict raw material availability and demand in chemical production. AI forecasting allows flexibility throughout molecule development stages, adjusting processes accordingly. Additionally, AI predicts future material prices, enabling rapid production adjustments to market changes, thereby minimizing financial losses.

In the chemical industry, AI reduces forecasting errors by 50% compared to human methods, optimizing supply chain efficiency and preventing overstocking by accurately forecasting demand.

Increased Quality Assurance

Our AI model plays a crucial role in accident prevention on product lines by detecting and mitigating potential incidents. We train our ML algorithms to learn from past occurrences to enhance efficiency in addressing similar issues in the future. We can help you empower your optical systems with our AI services for defect detection like mechanical inclusions, color differences, damaged packaging, and many more. The AI-enabled system increases the accuracy of data collection and accelerates the model validation process.

In chemical production, quality assurance relies significantly on computer vision. Deep learning algorithms enable computers to scan substances on production lines, assess their properties, and classify them accurately.

30-40% Increased Accuracy In Resource Allocation

Chemical industries possess dynamic resources and require an alignment among all the departments engaged in the production process. ERPs and CRMs can do wonders with effective resource allocation among different departments of the chemical industries.

Our services like custom software development, data (AI/ML) solutions, and product reengineering and modernization help chemical industries utilize their resources more effectively increasing their utilization up to 30-40% eventually increasing productivity and ROI.

Why Are Chemical Industries Partnering With AQe Digital?

- Specialized AI and ML Solutions: AQe Digital offers specialized AI and machine learning (ML) solutions tailored to manufacturing industries’ needs, ensuring precision, agility, and scalability in data analytics and decision-making.

- Cost-effective AI Strategies: AQe Digital’s AI and ML solutions are designed to optimize costs without compromising on performance. By leveraging advanced technologies and efficient data processing techniques, AQe Digital enhances operational efficiency and maximizes ROI, offering superior cost-effectiveness compared to competitors.

- Reliability and Transparency: As a successful digital solution provider AQe Digital has come a long way- more than 26 years. Our industry expertise, professionalism, transparency, and strive to deliver the best innovative result-oriented solutions helped us have a 93% client retention rate.

- Personalized Engagement: Our entire team pays granular attention to every detail of the project- right from conception to deployment. However, to leave no stone unturned the top brasses of the organization stay involved around all the stages of services we offer. Our clients have unhindered access to the CEO, CXO, CTO, and other top brasses of an organization during the entire project stages ensuring top-notch service and timely delivery.

Conclusion

Custom workflow automation technologies have transformed the chemical industries by boosting safety, productivity, quality control, and cost efficiency leveraging advanced technologies. Automation is the future of the chemical industries, driven by advancements in machine learning, artificial intelligence, and the Industrial Internet of Things (IIoT). These innovations will enable real-time decision-making, optimize production processes, and enhance safety and quality control. Automation has become an essential tool for the industry to remain competitive and meet regulatory requirements.

Contact us to discover how our comprehensive digital solutions can transform your chemical manufacturing processes. Leverage our 27+ years of experience as a tech solution provider to make your chemical manufacturing or processing unit equipped with next-gen technologies.