Digital transformation in manufacturing is pretty much directed at how companies are managing their warehouses-the new revolution in the logistics industry. Have been WMS ever since before; most of the logistics operations rely on the old, outdated, and no longer possible systems of operation to respond quite to the speed, movement, and technological advances needed by the market today.

More than 90% of the warehouses are already adopting or are set to adopt some advanced warehouse management systems (WMS) in the future. This clearly signals a change in the perspective of logistics leaders toward technology. Many have finally realized that old systems simply cannot cut it anymore. To be wasteful, if your warehouse relies on legacy WMS, you’re not just missing out on value; you’re really falling behind.

This is really a customer-oriented market, and inefficiencies due to legacy systems and processes are no longer tenable. Slow processes, human errors, and poor inventory tracking put operations at great risk. The clock ticks: failure to modernize among logistics firms will push them against the wall of their decline in meeting the requirements of real-time tracking, order fulfillment, and seamless integration throughout the supply chain. Stagnant: higher operational costs with lower customer satisfaction and, eventually, loss of competitive advantage.

Now is the time to act! Let’s examine how your business could use AI-based solutions to improve logistics management.

Why Legacy Warehouse Management Systems (WMS) Are Holding You Back?

Legacy WMS systems were once very important for logistics. They facilitated the business of managing inventory and operations. But now, these old systems are more of a hindrance than a help. What once was good has now become a blockage to companies, slowing them down and creating inefficiencies in the pace of changes reshaping the logistics world. Here’s why continuing to rely on legacy WMS could be detrimental to your business:

Poor integrations with new technologies: These systems cannot integrate with new technologies such as artificial intelligence (AI), Internet of Things (IoT), and machine learning, to name a few. The result has been uncoordinated operations and missed opportunities.

- Scalability problems: As firms grow, the underperformance of legacy systems renders the expansion processes increasing hard and uneconomical.

- Inefficient operation: The outdated software contributes to the delay and lethargy of operation, which wastes time.

- Increased risk for error: Outdated algorithms and manual data input pose considerable risks for errors, causing missed deadlines and inaccuracies.

- Poor data accessibility: These systems are not capable of providing real-time updates, thereby diminishing the efficacy of making informed decisions on time.

- Outdated Reporting: Often late, reports with no live data amount to very poor decision-making.

- Labor-intensive Manual Work: Most of the work still needs manual input, requiring a highly disproportionate cost and a waste of increased productivity.

- Wasting resources: Limited automation means space and resources are wasted, which just slows down overall operations.

- Order fulfillment delayed: The slow pace of the old system reduces order fulfillment since it fails to meet the demands for quick processing and real-time tracking.

- Less personalized options: And such non-agile systems cannot provide customization: Hence, it greatly impedes customer satisfaction and loyalty.

- Old-time security: Outdated WMS incidents indicate creaking warehouses that are potential doors for data breach and compliance risks.

8 Ways AQe Digital Can Help You Integrate AI in Warehouse Management System

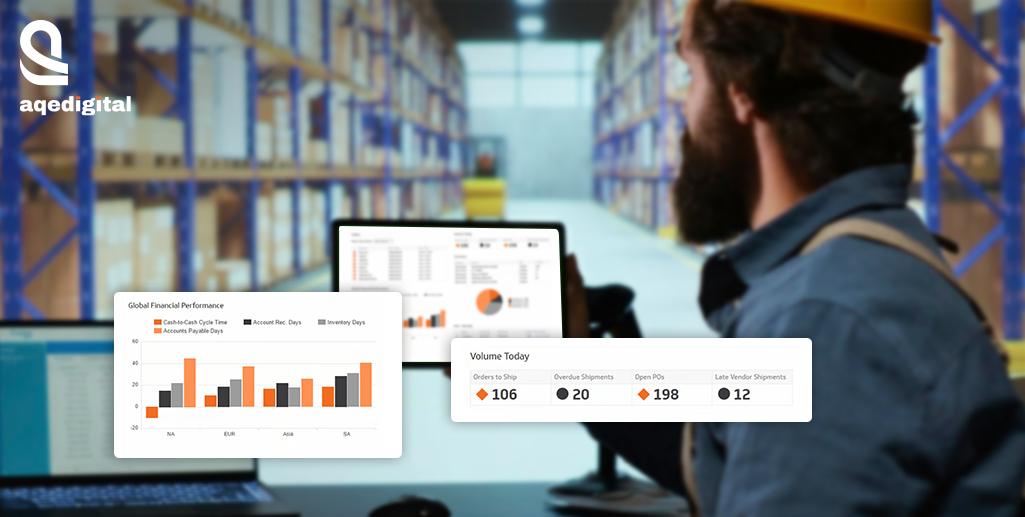

AQe Digital helps businesses to transform their warehouse system, using AI technology, instead of old legacy Warehouse Management Systems. Instead of replacing everything with an entirely new platform, we embed cutting-edge AI technology in your current system, unlocking its true potential and optimizing your existing infrastructure. Here is how AQe Digital uses AI in warehouse management:

1. Real-Time Inventory Tracking and Close Data Accuracy

Legacy Warehouse Management Systems are not always very accurate when it comes to tracking inventory, and by doing so, they increase the chances of experiencing stock-outs or sometimes even overstocked inventory. Adopting AI for demand forecasting has proven to be a bridge in achieving the success of real-time monitoring with inventory systems operating IoT devices, RFID, and AI-powered sensors to gather and provide you information. This can be effectively integrated with your existing WMS without the need to overhaul the entire system.

With automated data collection, each change, as with any good AI automation program, is now accurate, immediate, and in reality. No more manual entry. Real-time updates enable quick and accurate decision-making, which reduces the chances of human errors by integrating AI into your existing system, while also maintaining the stock levels to date.

- Benefits Associated with it:

- Increased Accuracy – Manual errors in tracking will no longer exist. The inventory levels are updated automatically by the AI systems, ensuring AI-driven inventory optimization to reduce costs and improve efficiency.

- Fewer Discrepancies – Minimal stockouts and excess stock is realized since real-time tracking ensures accurate and precise inventory records.

Our expertise in AI brings a real-time inventory counting feature to improve your current system’s providing live, accurate, current data visibility. While improving visibility by tracking inventory, the system helps eliminate discrepancies, ensure better stock accuracy, and allow better decisions to be made throughout your warehouse operations. AI-enhanced tracking empowers your team to take speedier decisions, safe in the knowledge that the data underpinning them is accurate.

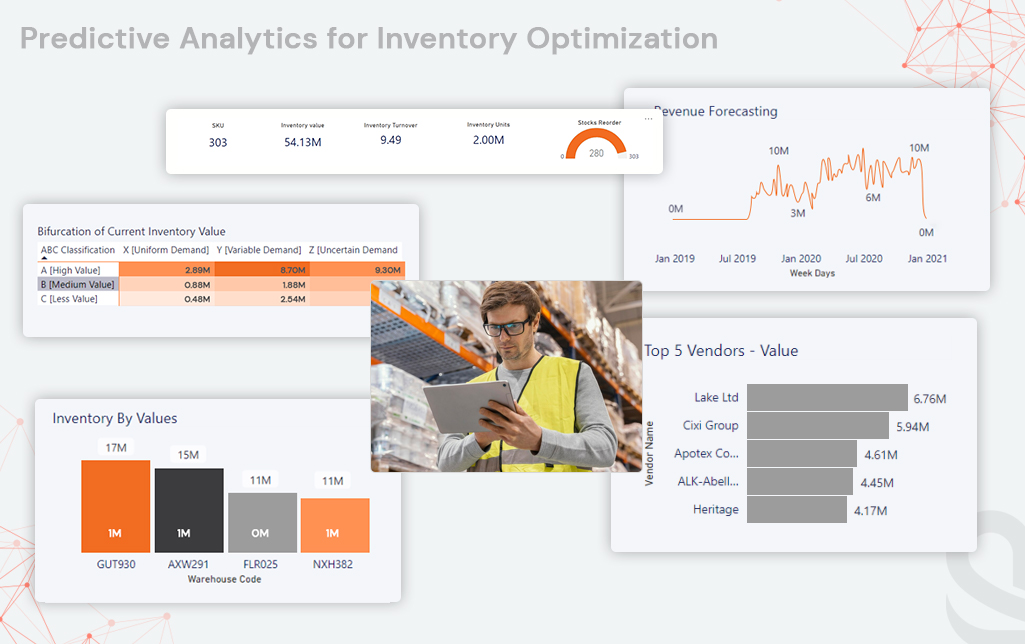

2. Predictive Analytics for Inventory Optimization

Legacy warehouse management systems operate from a perception of inventory demanding that it remain consistent with a yearly stock based on historical and in-sample data with no anticipated demand. Predictive analytics could be immersed in the pre-existing WMS to track past sales and trends demand to prepare forecasts for future needs. This overhauls the process of inventory stock by pointing to the actual forecast while production and procurement provide the right data that the company should expect to be in demand.

The AI in warehouse management is trained with the company’s known sales figures and previous market trends so that a forecast can be made within the same company. This might be done through indication about peak seasons, or days, setting a selling price, and driving promotions to understand when stocking needs will rise or come down. Predictive analytics tools help proactively replenish stock before it hits a critical threshold, making it unnecessary for humans to constantly monitor inventory in real-time. External Factors In: Inland, markets drive a sudden change at play, and much better any disruption in the supply chain-such as a transport strike-half of the tentative vehicles-cue AI eps.

- Benefits Associated with it:

- Reduced Overstocking and Stockouts – Improved AI in warehouse management anticipates greater demand better. This balances overstocking and ensures legacy merchandise stays for the shortest possible time.

- Smarter Purchasing Decisions – Forecasts are made in advance, integrating with the S&OP process based on real-time data and predictive analytics.

The use of cost-efficient inventory management reduces potential expenses within the organizations and allows flexibility in scaling and adjusting to market demand within the scope of material movement. These AI-driven insights would make warehouse activity more smooth with shifting demands from consumers, resulting in better cost-efficient service delivery and increased operations agility.

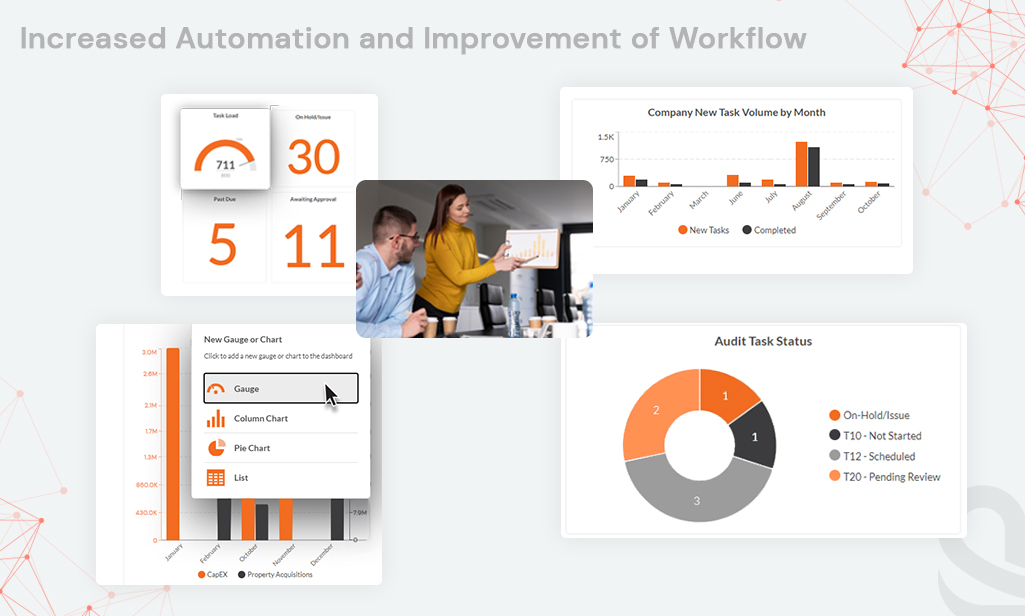

3. Increased Automation and Improvement of Workflow

The inefficient ways, often filled with chances for mistakes, guarantee that legacy systems, in most cases, depend on manual labor for repetitive tasks. Some AI-assisted automation technologies in use today, including robotics and intelligent conveyors, give the power to the current system to perform tasks with lower error rates and at a faster pace. This form of automation directly interfaces with your already existing WMS to complement and synchronize your operations while suffering little or no disruption to your workflow.

AI in warehouse management also assists with the flow of goods through the warehouse to position the product in the optimal locations while facilitating the routing for minimal pick time. Collaborative Robots lift heavy items, sort packages, and move products with speed and precision side by side with human workers.

- Benefits Associated with it:

- Increased Throughput – Automation accelerates repetitive tasks, thus speeding up order fulfillment.

- Reduced Human Error – Manual processes are reduced, minimizing potential errors caused by fatigue or oversight through automation.

We put AI automation on your processes to streamline tasks that include picking, packing, and shipping. As we manage to set up automation within these essential processes, we reduce manual involvement, quicken turnaround times, and minimize errors. This reflects impressive operational efficiency due to reduced costs and transforming workforce productivity within existing systems.

4. Improved Order Fulfillment and Customer Satisfaction

Legacy systems do not work up to the mark in terms of prioritization, routing, and tracking. This causes many delays in providing maximum customer satisfaction. AI is bringing all-around automation in order fulfillment, namely intelligent order prioritization, optimized picking path, and real-time tracking given to customers and staff. AI systems are dynamic systems that prioritize orders differently, based on delivery deadlines, availability of goods, or classification of customers. This way very important orders will always come first. Artificial intelligence provides algorithms which will optimize the product movement within the warehouse so as to get the shorter and the most efficient route for picking and packing. Moreover, customers and warehouse managers can have real-time visibility of status of orders thus reducing all uncertainty and bringing about transparency with AI-powered WMS.

- Benefits Associated with it:

- Time-saving Order Processing – Optimized Routing and Intelligent Prioritization contribute to rapid order processing.

- Boost Satisfaction Experience by Customer – Keeping customers informed with real-time updates contributes to greater satisfaction.

With AQe Digital, AI in warehouse management improvements in enhancing order fulfillment processes-picking routes, processing times, and delivery schedules will result in faster and more accurate order completion, thus raising customer satisfaction. Timely, faultless deliveries will then be expected from customers, thereby consolidating their expectations and confidence in doing business with you.

5. Scalability and Flexibility

The legacy warehouse system is not very good at scaling whenever business growth happens and usually needs expensive upgrading, which tends to consume too much time. An AI system, on the other hand, is designed to be hassle-free and flexible in adding new features for businesses, warehouse expansion, or increasing capacity without replacing the entire infrastructure from scratch. New AI tools can be added modularly at the point of need-increasing your functionality-as with adding new process automation or enhancing predictive analytics- and it’s that easy to scale AI within your warehouse. Using cloud AI tools, geographical space has no more restrictions in expanding the operation over different warehouses or regions – no need for on-site hardware installations or extreme system upgrades. An appropriate AI system integrates seamlessly with your existing WMS, scaling up or down as your needs change without interfering with ongoing operations.

- Benefits Associated with it:

- Growth Without Efforts – New features or capabilities can be implemented to keep up with business growth.

- Economical Scaling – AI doesn’t mandatorily require a full-system replacement but can be extended as needed.

AQe Digital’s AI in warehouse management consultation will scale as your business grows. Whether you’re moving into additional territories or simply increasing inventory or order numbers, our AI integration will grow with you. We will enhance your current WMS with AI technology, capable of scaling as per your needs and not requiring disruptive changes or big overhauls of your existing system.

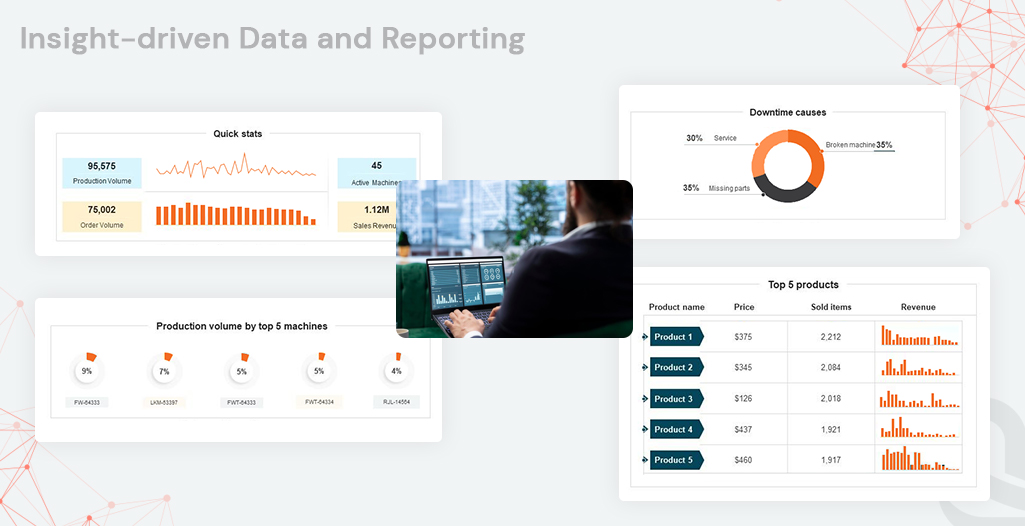

6. Insight-driven Data and Reporting

Artificial Intelligence has become more of a real-time analysis mechanism than a support system for previous-generation, legacy WMS applications. Thus, all data flowing unpackaged in warehouse-out finds its way into actionable strategic insights, where trends and operational inefficiencies are being constantly monitored with improvement recommendations. The insights are then custom-reported on centralized dashboards for organizational stakeholders to measure KPIs and the effectiveness of their operational enhancements. The custom dashboards embedded in the advanced analytics solution can offer key metrics-stock levels, order accuracy, and warehouse performance-reports in real-time that allow users to make educated decisions. AI detects discrepancies in operations, leading to inefficiencies that allow timely intervention before they become a big problem.

- Benefits Associated with it:

- Data-driven Decisions – Smarter insights translate to smarter decision-making, enabling the creation of more efficient operations.

- Operational Transparency – All stakeholders, with real-time reporting, are informed and can take action based on data at the right time.

Your data will enter the world of action with our insights about AI in warehouse management. Our improvement in the existing reporting capacities makes it possible to offer real-time, data-driven insights to monitor, direct, and enhance warehouse performance. Such insights will empower your team to enhance the way they learn and make decisions, therefore keeping you relevant and always ready to adjust to market trends.

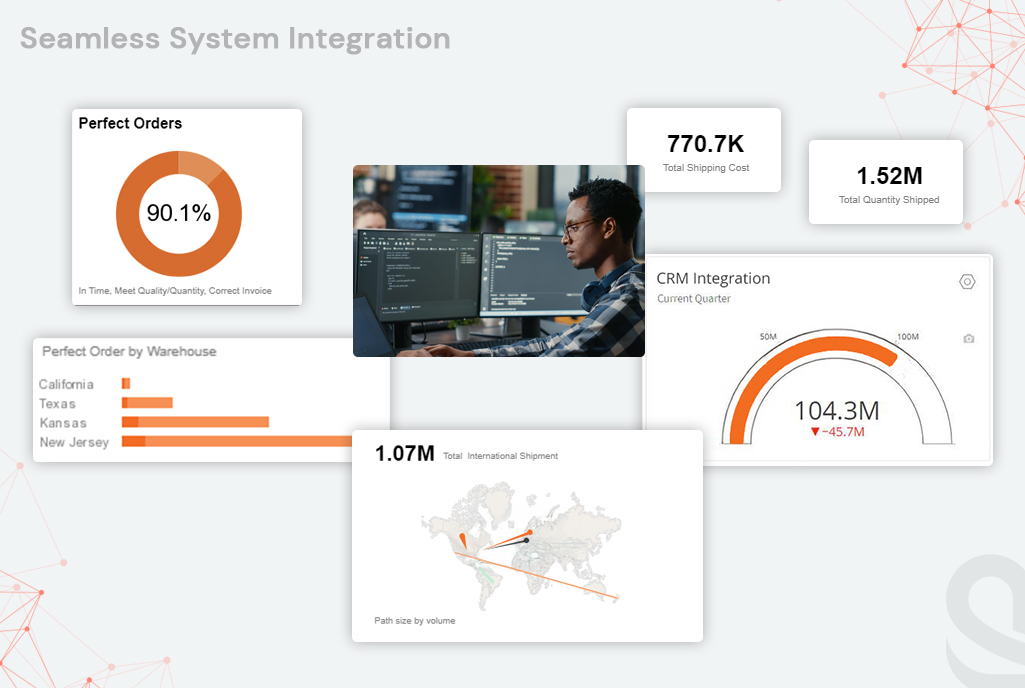

7. Seamless System Integration

AI-powered legacy systems will improve the performance of your existing warehouse management software, ERP, etc. while remaining functional. As AI applications are introduced not by replacing everything instantaneously, but rather as add-ons to existing tools, the possibility for minimal interruption becomes present. Through APIs, AI can connect to existing systems in real time and enable different platforms (WMS, ERP, TMS, etc.) to communicate. Moreover, you don’t need to replace existing systems completely; those systems can be improved without replacing them by introducing AI into warehouse processes in increments. AI integrated together all existing systems, ensuring that all data flows and operations are synchronized.

- Benefits Associated with it:

- Minimal Disruption – The most significant benefit AI integration brings is minimal disruption, ensuring ongoing operations are not hampered.

- Smooth Transition – AI integration experts complement legacy WMS, making it easier to upgrade.

AQe Digital puts its best on the effort of integrating that AI technology with whatever existing system it operates: ERP, CRM, or other supply chain management tools. A good integration solution ensures that there is smooth data flow across the whole platform, which indeed brings about better coordination and efficiency in operations. The least disruption and maximum compatibility of systems together, is what would ensure that maximum possible value is drawn from existing technology.

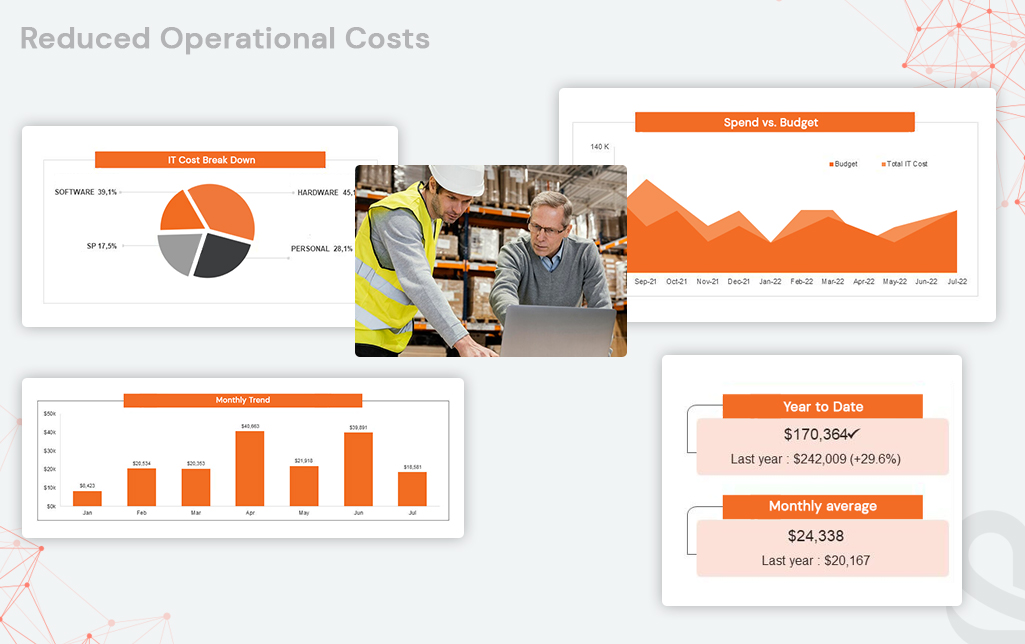

8. Reduced Operational Costs

AI driven automation, optimization of inventory, and predictive analytics have reduced labor costs and wastage in operations. By AI-integration into your existing WMS, processes can be streamlined without disrupting operations, increasing the performance of warehouse, and eliminating inefficient and unnecessary costs. Since AI handles all the repetitive tasks of sorting, picking, and packing, less manual labor is needed, and therefore reduces labor costs. For stock optimization AI minimizes stock holding costs by maintaining the optimal stock levels to avoid overstocking and reducing wasteful inventories. It can also make effective energy consumption management of a warehouse facility (lighting, HVAC systems), thus lowering overhead costs.

- Benefits Associated with it:

- Reduced Labor Costs – Automation reduces the need for manual labor, optimizing workforce efficiency.

- Savings for an Entity – More efficient operations lower costs related to power consumption and inventory holdings.

We help you automate the processes, lessening manual work by incorporating AI to streamline operational costs. Introducing AI into the systems shrinks workflow and reduces repetition while optimizing resources and further keeps costs low with increased productivity for the team’s focus on high-priority, value-added tasks.

Why a Homegrown Custom WMS Could Be the Perfect Solution for Your Business?

One of the biggest downsides of third-party WMS software is the ongoing subscription and licensing fees. Over time, these can become prohibitively expensive, particularly for smaller businesses or those experiencing rapid growth. A home-grown WMS can be your one-time investment with ongoing maintenance costs that can be scaled according to the company’s growth. This gives businesses more predictable budgeting and eliminates sudden price hikes or feature limitations tied to a subscription model.

Even if you have a well-built homegrown WMS, it can encounter performance issues as business demands grow, such as slow processing times, bottlenecks, or inefficient workflows. We identify and address these performance issues using the latest technological insights. By optimizing the system’s architecture, database queries, or workflows, you can enhance the speed and reliability of their WMS, allowing them to handle more transactions smoothly.

Most businesses, particularly the mid-sized businesses, usually get lured into the mostly expensive off-the-shelf Warehouse Management Systems. These typical systems bring with them tons of features, most of which do not fit the small-business definition, and add to this, the cost of hardware and maintenance is usually horrifying. But with your home-grown custom WMS, you do not have to procrastinate on these expensive system solutions.

At the end of the day, you deserve a WMS that works for you, not one that makes you pay for unnecessary extras.

So Are You Making Your Warehouse Smarter with AI?

There won’t be any real need to start it from scratch if you want to upgrade your warehouse. The AI could be integrated with warehouse management software running on your systems to deliver immediate benefits in tracking, operational optimization, and cost reduction. The needs will not include a complete transformation; rather, it will require smarter technology integration to work with its existing systems.

Here, at AQe Digital, we help you with a smooth integration of AI with full leverage on its potential. From workflow automation to insight improvement on your inventory, we ensure your warehouse is future-ready.